IF A MODERATOR IS READING THIS THEN PLEASE REMOVE THE IMAGES FROM ‘Dozens of original recipes by Sales and Pollard and Taddy & Co Rediscovered in Museum Archive’ Once this has been done I will apply to the museum for permission to use their images on this forum. Until then I can’t upload any more pictures which is a shame as I have a great many interesting finds. Thank you.

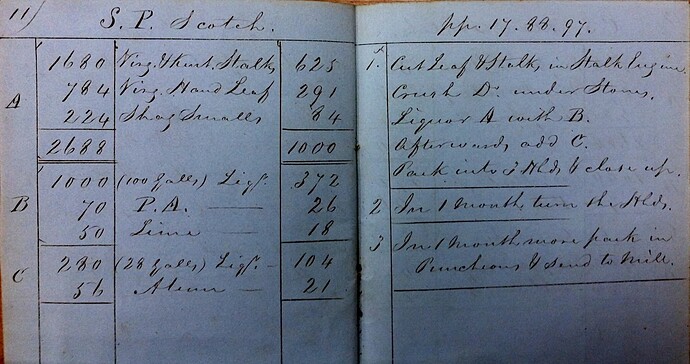

A hundredweight (cwt) is here 112 pounds in weight. Puncheons are barrels holding 132 gallons or more. Hhd referred to in the text means Hogshead. Pot liquor = 4 gallons: cisterns 1 inch = 5 gallons. Bin L=11 ft, D=5ft, W=8ft.

Lime, Pearl Ash and Alum is measured in what appears to be ‘ts’ which I guess means ‘tsp’ or ‘teaspoon’ but I’m not certain. The earliest patent for Pearl Ash in the UK is dated 1749.

I’ve rewritten the recipe so it makes more sense (to me) but the original text is at the bottom. The entire process of fermentation, stacking and liquoring would without doubt make much more sense to anyone here who processes tobacco for snuff. Perhaps anyone with that knowledge reading this could compare this process with that used today (which is likely very similar) and hazard a guess what this S.P would be like.

S.P SCOTCH

Take 15 cwt (1,680lbs) good stalks cut in the machine and 9 cwt (1,008lb) Fine Rich Virginia Hand Leaf (which has been cut in the stalk machine and run under large stones sufficiently to bruise it so that it may take the liquor more easily) [See note at end regarding shag smalls and stalk mixtures]

Each tobacco type is placed in bags of 56lb in weight. [30 bags of Stalk and 18 bags of Leaf]

Dissolve in the upper cistern 70ts Pearl Ash (potassium carbonate) in 100 gallons of water.

Slack in the lower cistern 50ts lime.

Put 5 bags of Leaf out to the bin and make them level.

Let the Pearl Ash water (upper cistern) into the lime (lower cistern) and keep stirring it while applying 3 pots to the first layer of leaf

the 2nd layer - 4 bags Stalk and 3 pots

the 3rd layer - 4 bags Stalk and 3 pots

the 4th layer - 4 bags Leaf and 3 pots

the 5th layer - 4 bags Stalk and 3 pots

the 6th layer - 4 bags Stalk and 3 pots

the 7th layer - 4 bags Leaf and 2 pots

the 8th layer - 4 bags Stalk and 3 pots

the 9th layer - 4 bags Leaf and the remaining liquor (2 pots.)

Then take 5 bags of stalks and rake them well (the remaining bag of leaf used on a floor between the cistern and bin to keep it dry) and into this drain the cistern, not removing the lime left but put into it 56ts Alum with 28 gallons of hot water gradually - 2 or 3 pots at a time.

When it is dissolved put 3 pots on the layer and then 5 bags of stalk and with the remaining liquor wash the top of the bin so that it may not show white. Let it lay 24 hours, turn it and pack it tight into 3 hogsheads. Let it remain for 2 months during which time turn the hogsheads over once and then unpack it into puncheons and send it to the mill for grinding.

S.P SCOTCH (original text)

Take 15 cwt good stalks cut in machine and 9 cwt Fine Rich Virginia hand Leaf (which has been cut in the stalk machine and run under large stones sufficiently to bruise it that it may take liquor more kindly) each weighed in bags of 56. Dissolve in the upper cistern 70ts Pearl Ash in 100 Gallons water. Slack in the lower one 50ts lime then put 5 bags leaf out to the bin – make them level and letting the P.A water into the lime and keeping it stirred up you put your pot in and take 3 pots to this layer of leaf the next layer is 4 Bags of Stalk & 3 pots the 3rd layer 4 bags Stalk 3 pots the 4th layer 4 bags Leaf & 3 pots 5th 4 bags Stalk & 3 pots 6th layer 4 bags Stalk 3 pots 7th 4 bags Leaf & 2 pots 8th layer 4 bags Stalks & 3 pots 9th layer 4 bags Leaf and the remaining liquor (2 pots.) then put 5 bags Stalks and rake them well (the one odd bag of Leaf used on a floor between cistern and bin to keep it dry) and into this drain the cistern well not removing the lime left but put into it 56ts Alum with 28 Gallons hot water gradually (i.e 2 or 3 pots at a time) when dissolved put 3 pots on layer then 5 bags and with the remainder of liquor wash the top of bin so that it may not show white. Let it lay 24 hours, turn it and pack it tight into 3 Hhds , let it remain 2 months during which time turn the Hhds over once and then unpack it into puncheons and send it to the grind.

Note: A succinct version of this recipe for S.P Scotch, beautifully written, which I would like to upload as an image, lists 784lbs Virginia Hand Leaf and 224lbs Shag Smalls which together make the 1008lbs leaf. It stipulates a mixture of Virginia and Kentucky stalks. The version also mentions an engine which could have been the ‘10 Horse Engine’ for cutting supplied in 1811 - the year Dandy George became Regent. Otherwise it’s the same recipe as above.

The manufacturer could make three parcels of S.P (snuff -work) in a day. What is noteworthy is the difference in weights, for example: 2,328lb 2,478lb and 2,412lb parcels - a difference of 150lb between the lightest and heaviest parcel. This suggests a very slight variation in taste between parcels.

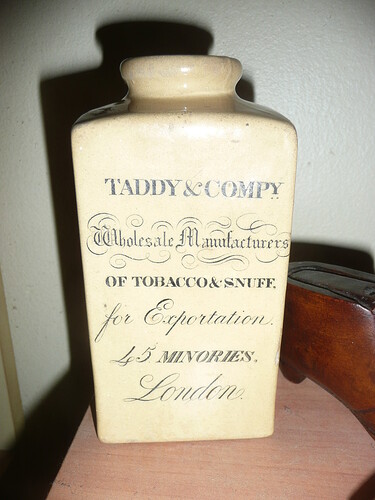

References to S.P 100 occur quite often in the Taddy & Co recipes. The significance of 100 (at least according to my source) is that the S.P has been mixed with another Scotch with 100 parts S.P hence S.P 100. Examples listed include No.1, Jefferson’s Mixture and S.F.

There is no reason to doubt that this system of nomenclature also applies to Wilson’s S.P 100 and that it is a mixture using 100 parts unscented S.P to whatever else is used in the mixture. I hope this clears up the mystery regarding the meaning of 100.

It’s interesting that Wilsons of Sharrow claim that their S.P 100 is similar to J&H Wilson’s S.P No.1. If the latter is made with 100 parts S.P like Taddy and Co’s S.P No.1 then this is hardly surprising.